Don´t miss it!

Exciting automation solutions for every user are waiting for you!

Part I: Greater flexibility and modularity through robotics and scalable automation

When?

Thursday, March 25, 2021

9.30 am - 10.30 am CET

Thursday, March 25, 2021

9.30 am - 10.30 am CET

The following topics are waiting for you:

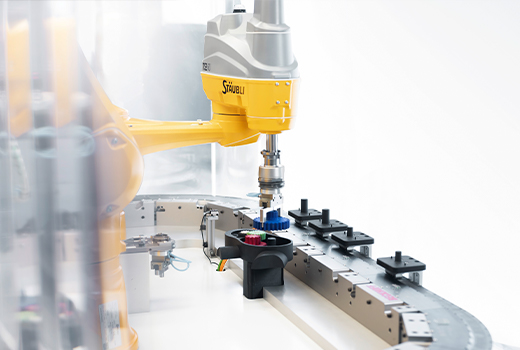

Stäubli robots with CS9 controllers - High performance for digitally networked production

Stäubli Robotics offers Industry 4.0-compatible solutions for your connected production. Learn more about the wide range of Stäubli SCARA and six-axis robots for low and medium payloads and, all sensitive environments and the high connectivity of CS9 controllers.

Flexible production possibilities via a flexible intelligent transport system

With the XTS (eXtended transport system) linear transport system, Beckhoff offers an intelligent drive solution in which magnetically driven movers travel along a path consisting of fully integrated motor modules. The integration of the robots into the Beckhoff controller, in combination with the XTS solution, gives users a high degree of modularity and flexibility for their production processes.

Flexible and scalable automation thanks to robotics and XTS from Beckhoff

Using the example of a fully automated assembly cell, you will learn about the long-term and sustainable benefits of a flexible controller based on Beckhoff and Stäubli robot systems, how new product groups can easily be realized and implemented, and how plant maintenance and expansion can be possible without special robot programming knowledge.

Part II: Robot integration into a higher level of control with Beckhoff TwinCAT SPS

When?

Wednesday, March 31, 2021

3.30 pm - 4.30 pm CET

Wednesday, March 31, 2021

3.30 pm - 4.30 pm CET

Be excited about the following topics:

Easy robot integration into higher-level controls

Find out which product solution is right for you and for your task. Stäubli Robotics offers three flexible solutions for programming and integrating all robot kinematics: VAL 3, a powerful environment for all sophisticated and customized robot solutions; uniVAL plc for all PLC programmers, where the robot is controlled via function blocks in the PLC; and uniVAL drive for hardware-based integration at the drive level, allowing the programmer and user to remain in their accustomed environments.

uniVAL drive for deep integration of the robot into complex motion sequences

In addition to routine handling tasks, robots are increasingly being used for complex machining processes. Typical CNC processes, up to plate cam machining, are implemented with a robot. Stäubli’s uniVAL drive provides an open interface that optimally meets this challenge with TwinCAT from Beckhoff Automation.