CUSTOMER'S WORD

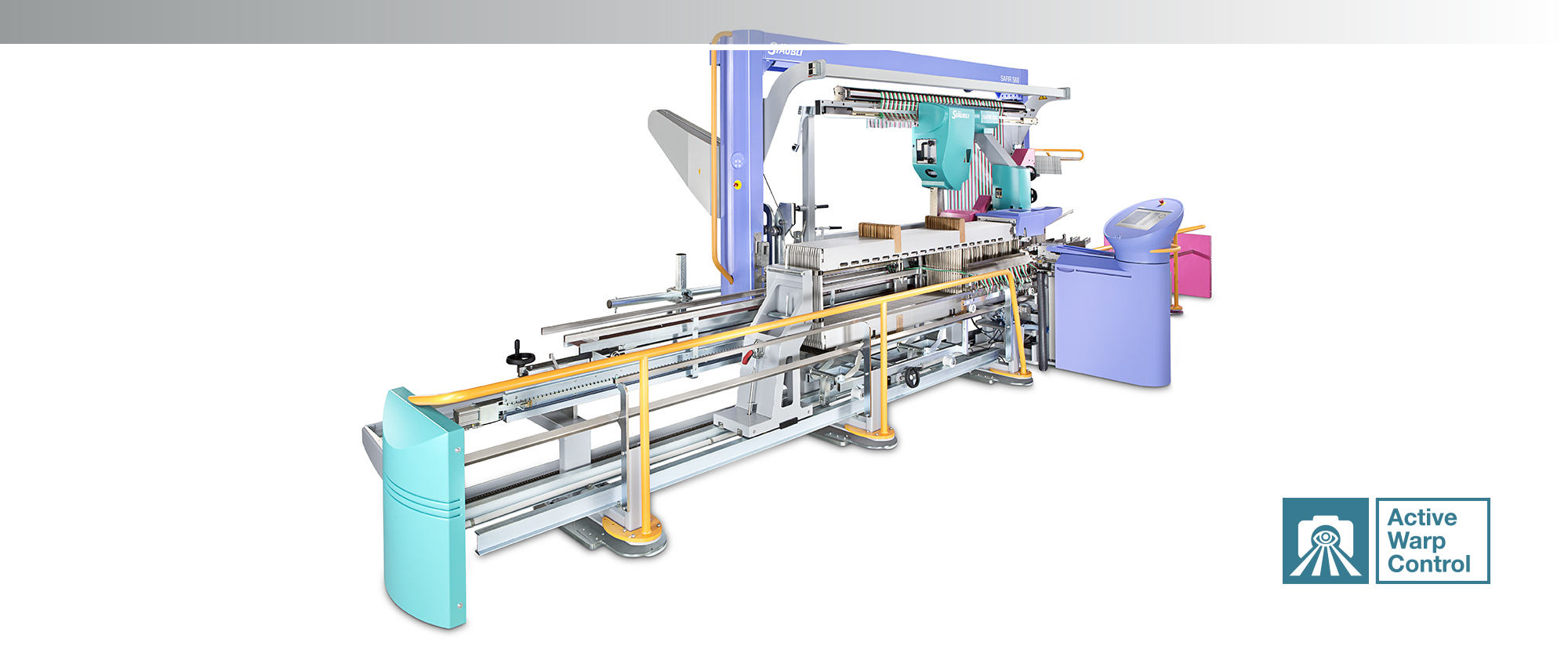

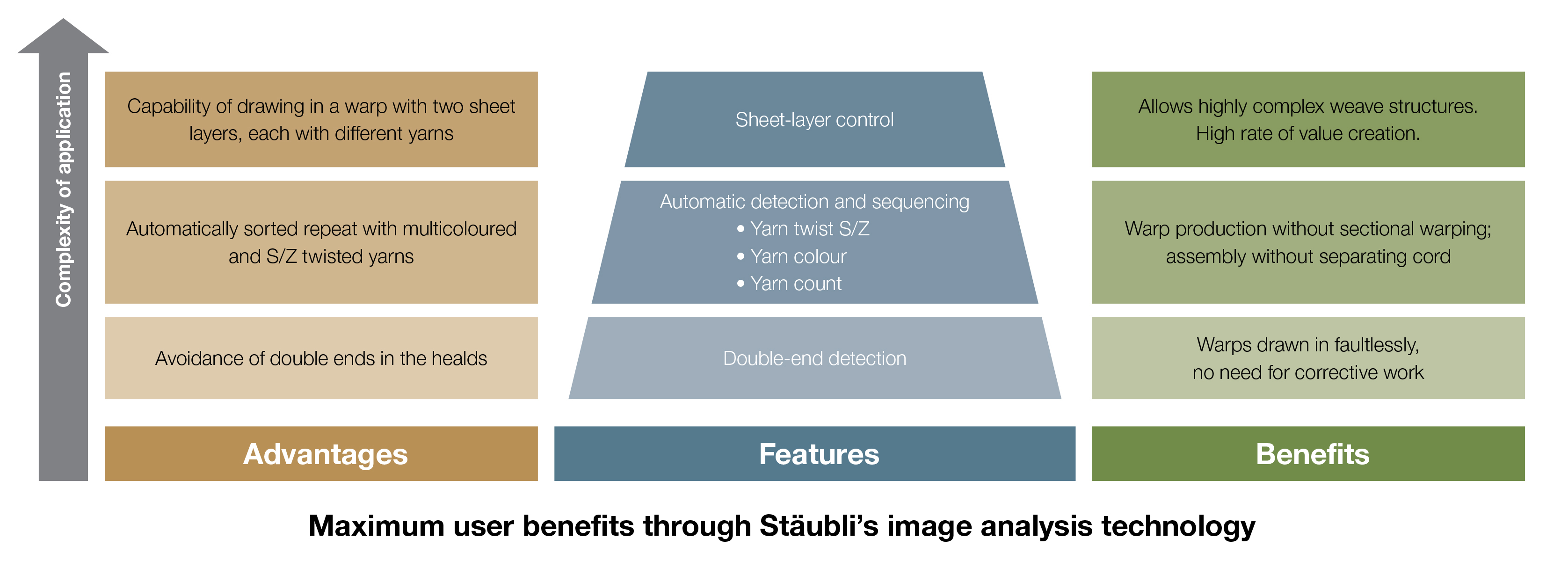

"Capability and agility for premium fabric processing. To achieve both high productivity and agility, Fraas has been counting on Stäubli shed motions such as electronic rotary dobbies and Jacquard machines since the 1980s, and the company recently decided to invest in a new SAFIR S60 automatic drawing-in machine. With its unique yarn separation system, this machine supports perfect preparation of the warp and quality of the final product. Because Stäubli also provides reliable and prompt service and always continues to listens to customers about their needs and requirements, this success story will continue as long as winters are cold and people want to bundle up in beautiful scarves."

Alexander Schmidt, Board Member, the 5th generation of the founder Valentin Fraas

Alexander Schmidt, Board Member, the 5th generation of the founder Valentin Fraas