Stäubli Fluid Connectors | Advanced connection solutions for every industry

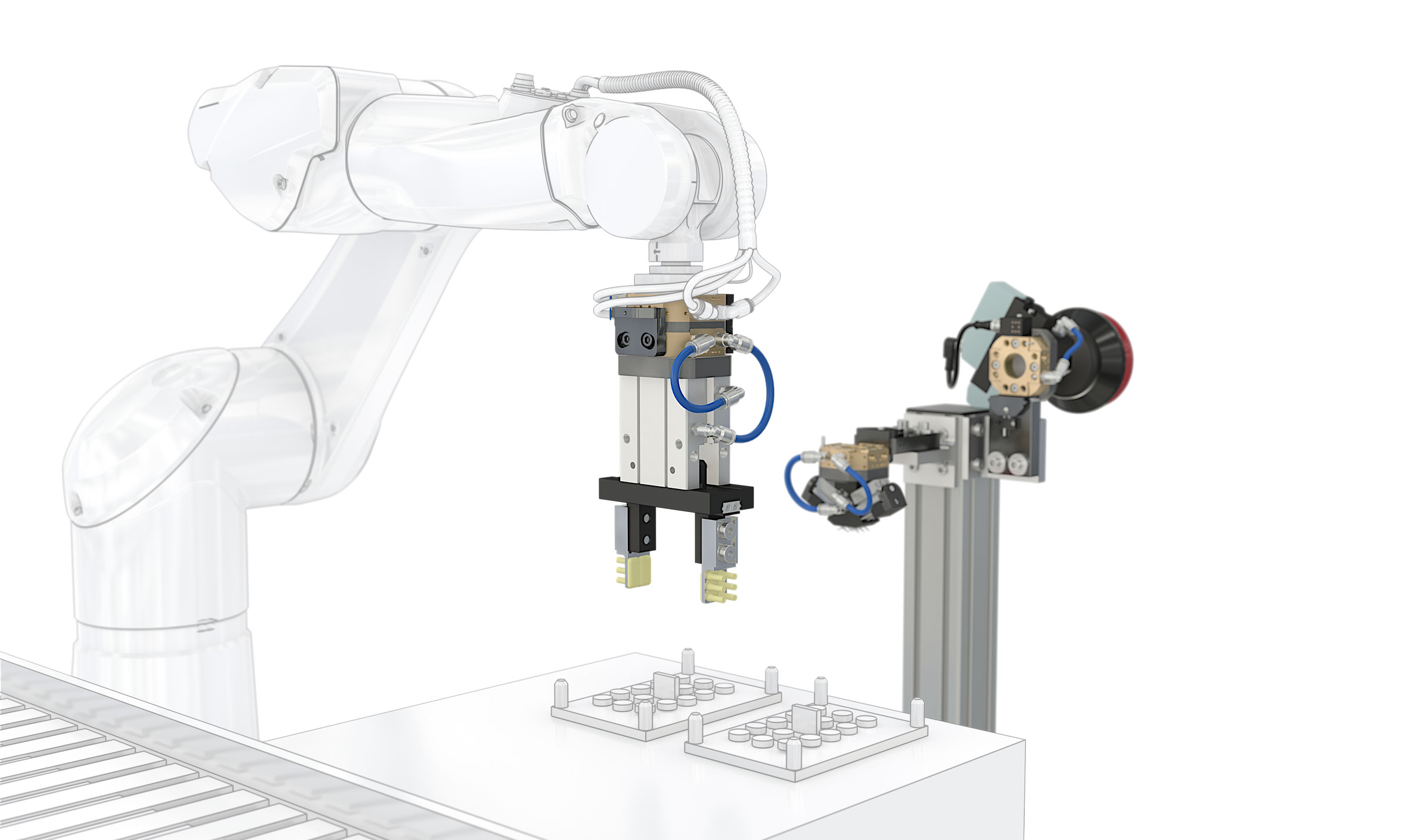

Flexible automation made easy: manual interface between FANUC CRX and SR series gripper system.

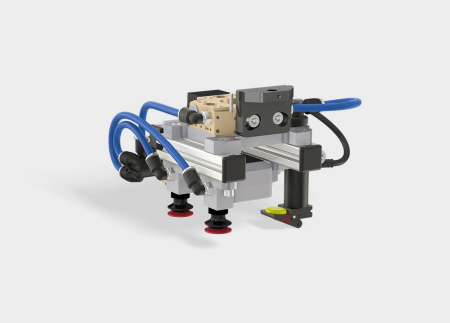

The manual interface between the FANUC CRX collaborative robot and the SR Series gripper system offers a high degree of flexibility and customization in robotic automation. This interface enables seamless integration of the robot and end-of-arm tooling, resulting in streamlined operations and increased productivity.

With this interface, operators can easily program the robot to pick, place and manipulate objects of various shapes and sizes. The SR Series gripper system provides safe and reliable gripping of objects, while the Fanuc CRX robot provides efficient and precise motion control. All in all, this manual interface is a powerful solution to meet the demands of modern manufacturing and automation.

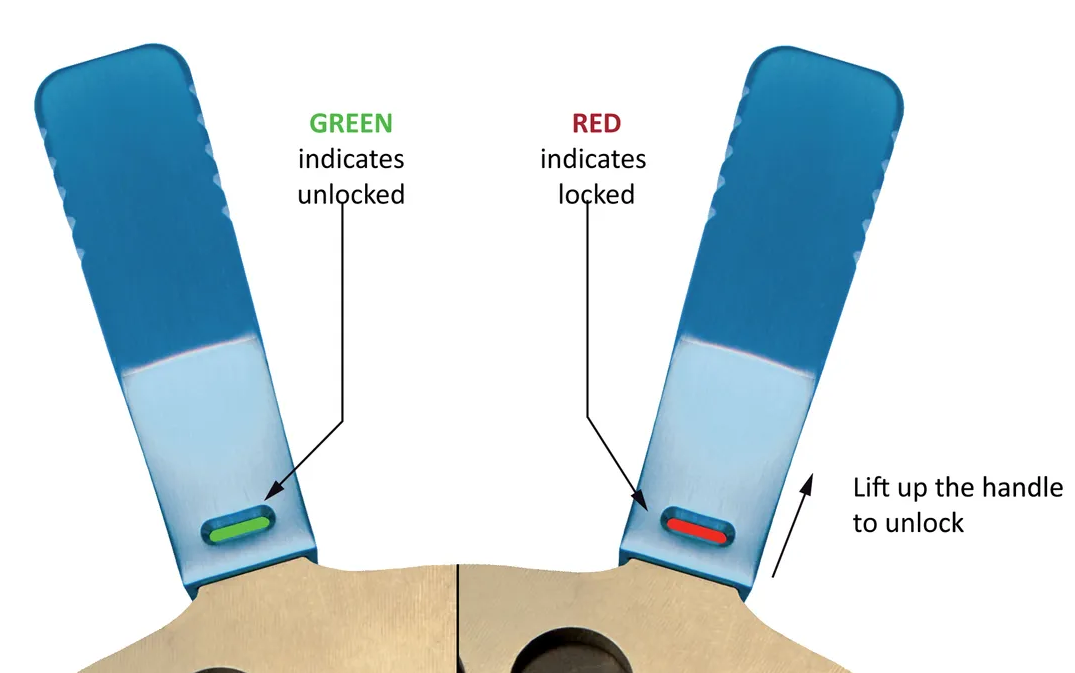

The handle in this design with the colored indicator is patented.

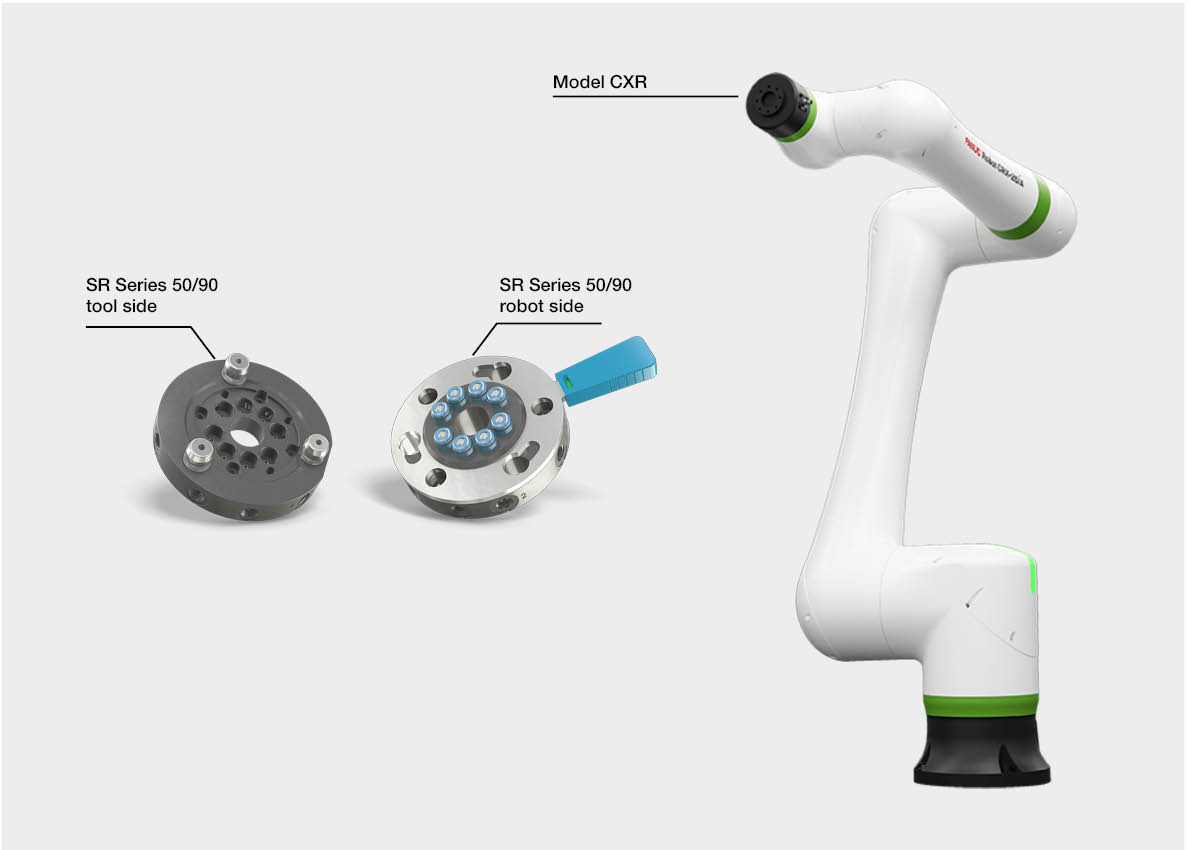

Matching models overview

20 kg payload

SR50

Quick-release plate with SAFE-LOCK locking, diam. 50 mm

40 kg payload

SR90

Quick-release plate with SAFE-LOCK locking, diam. 90 mm

Connection to FANUC CRX series

Connecting a manual gripper to the FANUC CRX series robot can be accomplished through a manual interface. The manual interface is a hardware kit that includes a mounting plate and electrical connections for the SR series gripper system.

How to connect to FANUC CRX series

Step 1:

Fix the adopter plate between CRX robot and SR-series.

Step 2:

Fix the robot side of SR-series to adopter plate.

Step 3:

Dock SR-series tool-side to robot-side by using the locking bar, it’s simply to rotate some angle (with SAFE-LOCK type, to lock/unlock like below by two actions).

Once installed, the gripper system is fully integrated with the FANUC CRX robot, allowing for seamless operation and precise control of the end-of-arm tooling.

General information

The SR Series quick-change system is a manual round system available in three sizes to meet different load requirements, including 20, 40 and 100 kg. Featuring an opto-mechanical locking mechanism, this new model offers improved process safety and clear indications of correct gripper replacement. To further enhance functionality, the extended version - the SR-MV model - is equipped with a highly effective micro-valve system that effectively blocks the air supply after disconnection. The Quick Change SR system can also transmit up to 13 sensor signals simultaneously, making it extremely versatile and ideal for a wide range of manufacturing applications.

- Manual interface between robot and gripper system

- Air connections always correctly aligned

- Body made of anodized aluminum alloy

- Model SL with secure SAFE-LOCK ensures maximum functional reliability and optical locking indication (red/green)

Resources

Automatic robotic tool changers

Automatic robotic tool changing systems increase the productivity in your manufacturing processes.

Contact us for more information

Get a consultation with our expert

STAUBLI KK

Nishinakajima 4-12-4

Yodogawa-ku, Osaka-shi

532-0011 OSAKA / JAPAN

〒532-0011

大阪府 大阪市淀川区 西中島4-12-4