PLASTICS WHITE PAPER

Production line changeovers: a critical moment for the plastics industry

Some plastics industry sites frequently juggle with several hundred and even over a thousand different moulds! Their productivity does not only depend on the performance of the machines. Downtime management often dictates whether productivity is won or lost. Injection mould changes are a mission-critical stage in the plastics industry. Remove the previous mould, clamp the new mould, connect/disconnect all the energy circuits, preheat the mould…. the amount of downtime can start racking up. However, these stages offer a great deal of room for optimisation.

"Using quick-release couplings

has saved us close to 40% on

our processes during production

line changeovers."

Denis P.

Methods Engineering

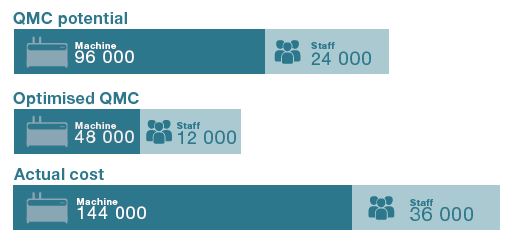

The gains made in terms of operator time and machine costs vary according to the sector, and even at sites within the same sector. The optimisation rate achieved with the QMC process responds to the specific expectations voiced by industry professionals.

Observe and measure: the real test

When measured in situ, the actual length of time required to carry out a production line changeover sometimes proves to be far longer than the theoretical time. Observing the operation therefore gives rise to organisational improvements.

The observers also identify manoeuvres that are dangerous for the operators handling the moulds. As a result, the test carried out on the whole of the line becomes key to improving productivity. This expertise justifies the recommendation of effective changes that will save time, boost flexibility, increase safety, enhance process reliability and guarantee the quality of the parts produced.

Read our complete white paper dedicated to the optimization of the Overall Equipment Effectiveness (OEE):